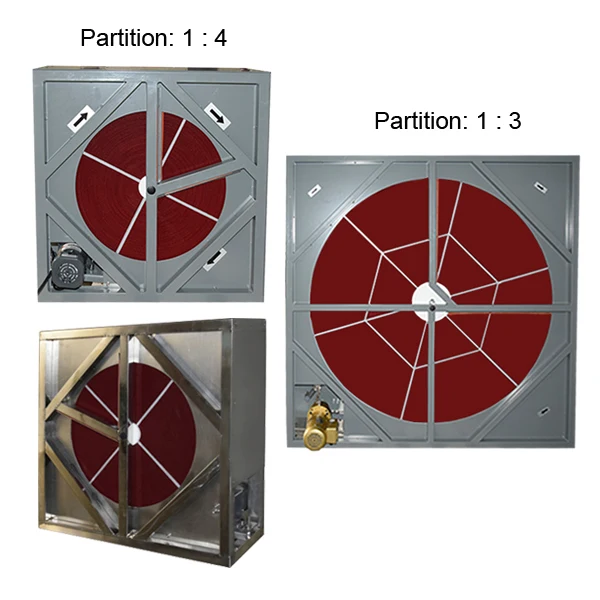

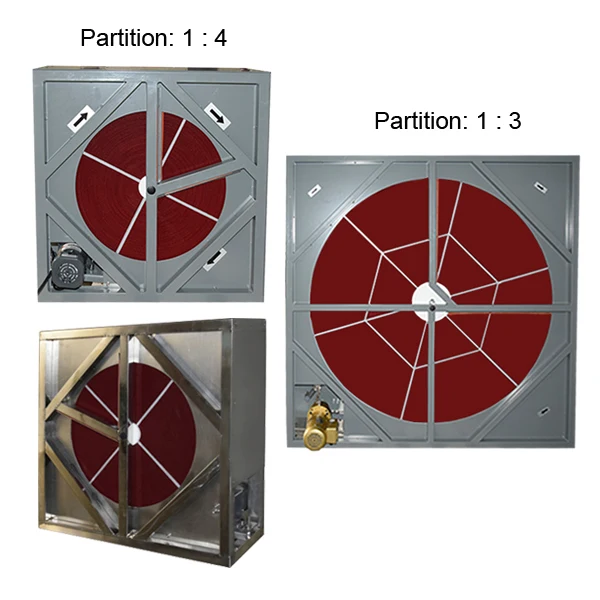

Partition 1 : 3

(1) High temp. regen. 120℃ ~ 140℃ , ordinary humidity 10% ~ 40%.

(2) Low dew point application.

(2) Low dew point application.

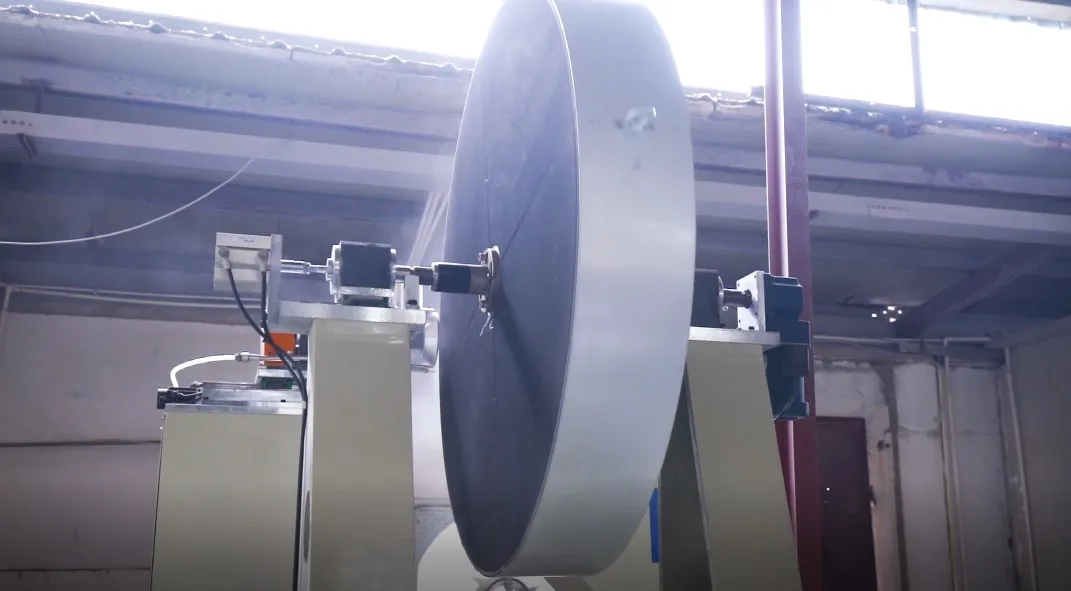

stainless steel cassette

puresci

| Availability: | |

|---|---|

| Quantity: | |

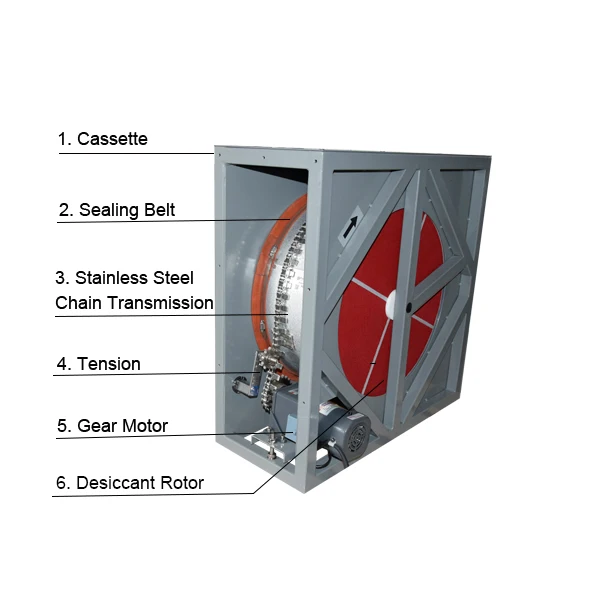

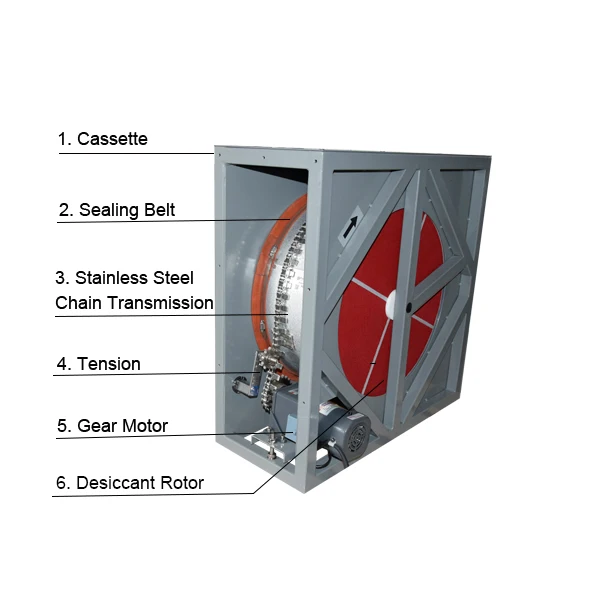

| 1. Cassette | (1) Cold drawn square tube, high temperature paint (2) Stainless steel square tube (3) Al-Zn plate |

| 2. Sealing Belt | Sealing-flat seal belt of silicone rubber and Teflon compound (High temp. resistance, low riction coefficient) |

| 3. Chain Transmission | Synchronous belt or stainless steel chain transmission. |

| 4. Tension | It is made of stainless steel. |

| 5. Gear Motor | Applicable environment is -10℃ ~ 40℃), Motor can be customized. |

| 6. Desiccant Rotor | 1. Common silica gel type: PSS 2. Energy-saving type: PSS-S 3. Low regen. temp. type: PSL-B |

| DESICCANT ROTOR WITH CASSETTE SIZE | |||

| Diameter(mm) | Thickness(mm) | Motor | Square Tube Size |

| 300-550 | 200, 300, 400 | 3 Phase 25W | 30*30mm |

| 600-750 | 200, 300, 400 | 3 Phase 40W | 40*40mm |

| 770-1070 | 200, 300, 400 | 3 Phase 60W | |

| 1220-1250 | 200, 300, 400 | 3 Phase 90w | |

| 1370-1525 | 200, 300, 400 | 3 Phase 90~100W | 50*50mm |

| 1730-2190 | 200, 300, 400 | 3 Phase 200W | |

| 1. Cassette | (1) Cold drawn square tube, high temperature paint (2) Stainless steel square tube (3) Al-Zn plate |

| 2. Sealing Belt | Sealing-flat seal belt of silicone rubber and Teflon compound (High temp. resistance, low riction coefficient) |

| 3. Chain Transmission | Synchronous belt or stainless steel chain transmission. |

| 4. Tension | It is made of stainless steel. |

| 5. Gear Motor | Applicable environment is -10℃ ~ 40℃), Motor can be customized. |

| 6. Desiccant Rotor | 1. Common silica gel type: PSS 2. Energy-saving type: PSS-S 3. Low regen. temp. type: PSL-B |

| DESICCANT ROTOR WITH CASSETTE SIZE | |||

| Diameter(mm) | Thickness(mm) | Motor | Square Tube Size |

| 300-550 | 200, 300, 400 | 3 Phase 25W | 30*30mm |

| 600-750 | 200, 300, 400 | 3 Phase 40W | 40*40mm |

| 770-1070 | 200, 300, 400 | 3 Phase 60W | |

| 1220-1250 | 200, 300, 400 | 3 Phase 90w | |

| 1370-1525 | 200, 300, 400 | 3 Phase 90~100W | 50*50mm |

| 1730-2190 | 200, 300, 400 | 3 Phase 200W | |

content is empty!