High-Efficiency Dehumidifier Wheel - Fast Moisture Absorption and Easy Replacement - For Lithium Battery/Pharmaceutical Dehumidifiers

Application range: Suitable for warehouses, workshops, laboratories, pharmaceutical factories and other places (temperature and humidity control ±2%RH).

-

FSTS-R370

-

Puresci

| Availability: | |

|---|---|

| Quantity: | |

|  |  |

FSTS-R280 is a high-efficiency and energy-saving dehumidification equipment, mainly composed of a dehumidification wheel, a transmission system, an air supply system, a regeneration system, a control system, etc.

Simulation research and calculation of combining computer simulation CFD, desiccant dehumidifier and other air conditioning systems.

| Parameters | FSTS-R280 | |

| Process fan | Airflow(m³/h) | 400 |

| EXT.pressure(pa) | 200 | |

| Motot power(kw) | 0.23 | |

| Rated voltage(VAC) | 230 | |

| Frequency(Hz) | 50 | |

| Noise(dBA) | 68 | |

| Regen fan | Airflow(m³/h) | 160 |

| EXT.pressure(pa) | 200 | |

| Motot power(kw) | 0.12 | |

| Rated voltage(VAC) | 230 | |

| Frequency(Hz) | 50 | |

| Noise(dBA) | 63 | |

| Motor | Power(W) | 30 |

| Torque(N·m) | 8 | |

| Voltage(V) | 220/customized | |

| Current(A) | 16 | |

| Weight(kg) | 76 | |

| Operating temperature(℃) | -20~45 | |

| Storage temperature(℃) | -20~60 | |

|  |  |

FSTS-R280 is a high-efficiency and energy-saving dehumidification equipment, mainly composed of a dehumidification wheel, a transmission system, an air supply system, a regeneration system, a control system, etc.

Simulation research and calculation of combining computer simulation CFD, desiccant dehumidifier and other air conditioning systems.

| Parameters | FSTS-R280 | |

| Process fan | Airflow(m³/h) | 400 |

| EXT.pressure(pa) | 200 | |

| Motot power(kw) | 0.23 | |

| Rated voltage(VAC) | 230 | |

| Frequency(Hz) | 50 | |

| Noise(dBA) | 68 | |

| Regen fan | Airflow(m³/h) | 160 |

| EXT.pressure(pa) | 200 | |

| Motot power(kw) | 0.12 | |

| Rated voltage(VAC) | 230 | |

| Frequency(Hz) | 50 | |

| Noise(dBA) | 63 | |

| Motor | Power(W) | 30 |

| Torque(N·m) | 8 | |

| Voltage(V) | 220/customized | |

| Current(A) | 16 | |

| Weight(kg) | 76 | |

| Operating temperature(℃) | -20~45 | |

| Storage temperature(℃) | -20~60 | |

Components

- Dehumidifying section of runner (including drying runner, regeneration fan, regeneration heater, regeneration filter and regeneration valve)

- Treatment fan section

- Front surface cooling section

- Rear surface cold section

- Primary effect filter section of treated air

- Medium and high efficiency filter section of treated air (optional)

- Air mixing section

- Electrical control panel

Rotary Dehumidifier Products Include:

Standard rotary dehumidifiers and combined rotary pulse humidifiers of various specifications, such as standard type, energy-saving type, low regeneration temperature type, and low demand point type, can meet the requirements of various operating environments and air parameters to achieve simultaneous control of temperature and humidity; At the same time, various non-standard dehumidification equipment can be customized according to user requirements.

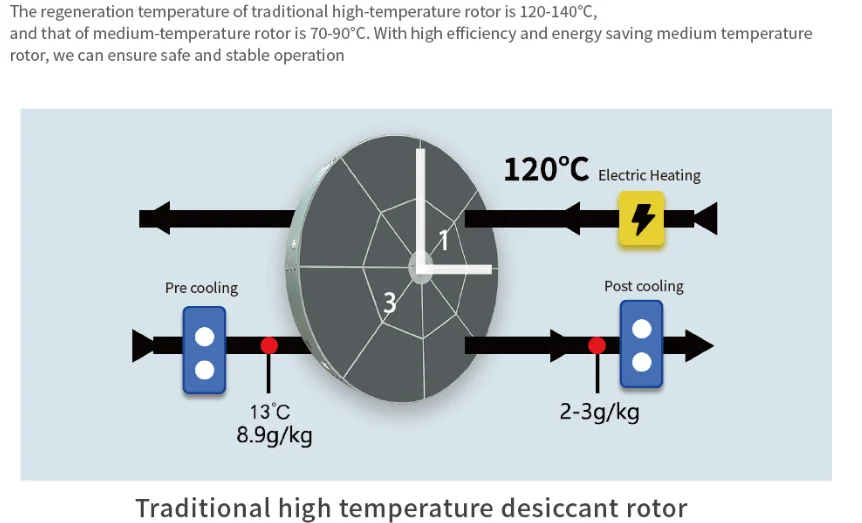

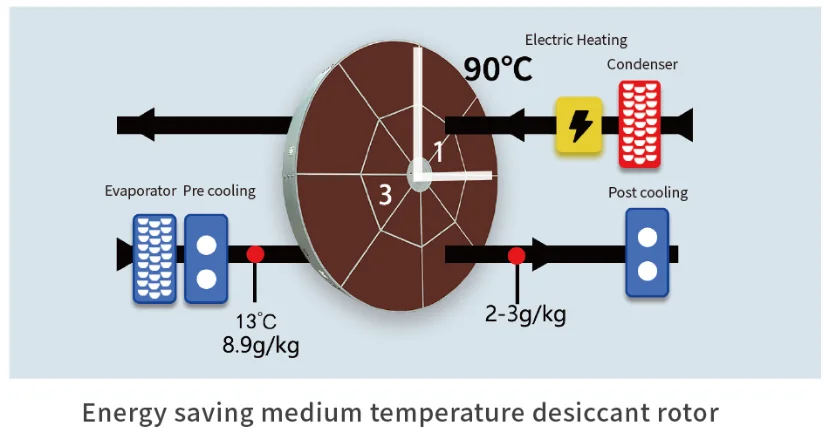

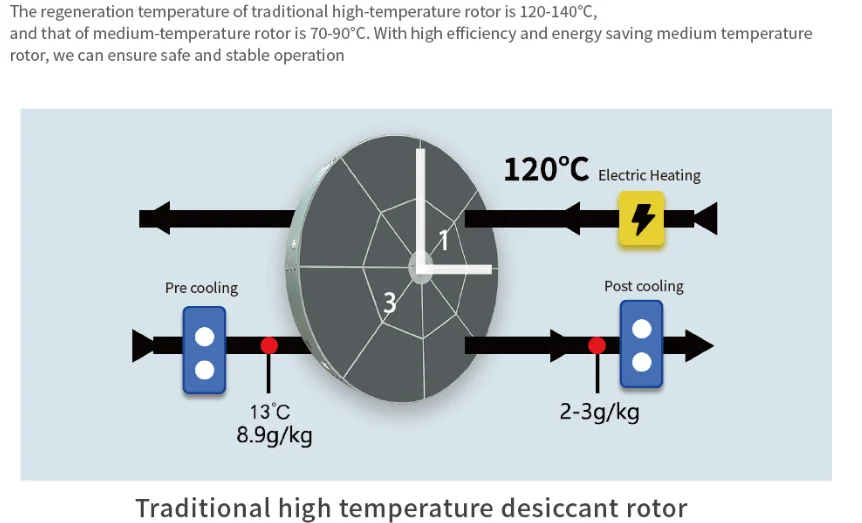

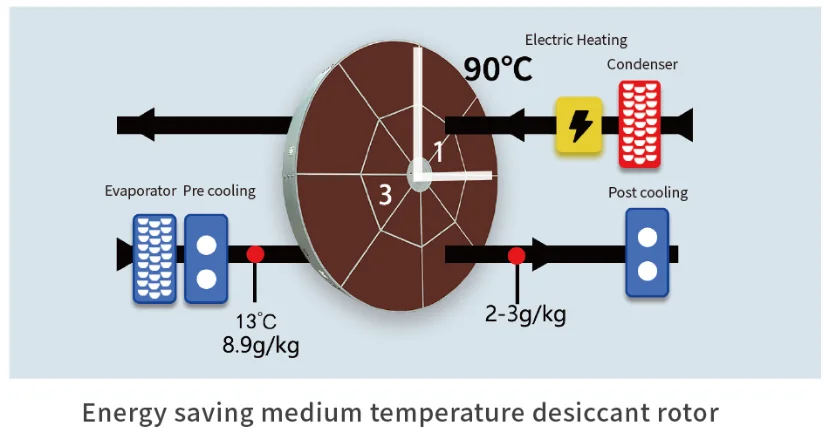

Adopt MTR & energy saving desiccant rotordeveloped by Puresci as core component

Various molecular sieve are mixed to reach the low dew point performance similar tothat of ordinary molecular rotor (high

temperature regeneration) in low dew pointworking condition. The regeneration temperature is also 20-40 °C lower than thatof the ordinary rotor. The breakthrough on adsorption materials can greatly reducethe regeneraion temperature, reduce the energy consumption of the whole machineand improve the operation safety while ensuring the dehumidification effect. Theregeneration temperature of the medium temperature rotor is 70~90 ° C, and theregeneration temperature can be lower than 70 ° C in a special low temperatureenvironment.

Several dehumidification materials be uniformly blend with inorganic fibers bygrafting.Multiple inorganic materials and zeolite materials are both with thecharacteristics of high water absorption capacity and deep adsorption ability.

Specifications

Desiccant dehumidifier controller adopts a single computer chip with high performance, which has the functions of

self-inspection, power off memory, LCD back light display, temperature and humidity adjustment, fault indication, etc,. Which is convenient to operate , safe, reliable and suitable for the place where humidity needs to be controlled.

Desiccant rotor, Process fan, Regeneration fan, Regeneration heater, Motor, Regeneration filter, Process filter, Controller,

Universal wheel, Process air duct, Regeneration air duct

manufacturing, and application research for more than ten years.

Design and manufacturing philosophy - In the process of designing and manufacturing desiccant dehumidifier, we are rigorous and serious to complete every detail with the philosophy of pursuing the essence and principle.

The optimization and serious selection of parts - optimize and improve the main components to ensure the product of high reliability and long service life. We cooperate with the best supplier in the world.

Dedicated to computer control technology combined with desiccant dehumidifier and other air conditioning systems to achieve all-weather and precise control by desiccant dehumidifier.

Components

- Dehumidifying section of runner (including drying runner, regeneration fan, regeneration heater, regeneration filter and regeneration valve)

- Treatment fan section

- Front surface cooling section

- Rear surface cold section

- Primary effect filter section of treated air

- Medium and high efficiency filter section of treated air (optional)

- Air mixing section

- Electrical control panel

Rotary Dehumidifier Products Include:

Standard rotary dehumidifiers and combined rotary pulse humidifiers of various specifications, such as standard type, energy-saving type, low regeneration temperature type, and low demand point type, can meet the requirements of various operating environments and air parameters to achieve simultaneous control of temperature and humidity; At the same time, various non-standard dehumidification equipment can be customized according to user requirements.

Adopt MTR & energy saving desiccant rotordeveloped by Puresci as core component

Various molecular sieve are mixed to reach the low dew point performance similar tothat of ordinary molecular rotor (high

temperature regeneration) in low dew pointworking condition. The regeneration temperature is also 20-40 °C lower than thatof the ordinary rotor. The breakthrough on adsorption materials can greatly reducethe regeneraion temperature, reduce the energy consumption of the whole machineand improve the operation safety while ensuring the dehumidification effect. Theregeneration temperature of the medium temperature rotor is 70~90 ° C, and theregeneration temperature can be lower than 70 ° C in a special low temperatureenvironment.

Several dehumidification materials be uniformly blend with inorganic fibers bygrafting.Multiple inorganic materials and zeolite materials are both with thecharacteristics of high water absorption capacity and deep adsorption ability.

Specifications

Desiccant dehumidifier controller adopts a single computer chip with high performance, which has the functions of

self-inspection, power off memory, LCD back light display, temperature and humidity adjustment, fault indication, etc,. Which is convenient to operate , safe, reliable and suitable for the place where humidity needs to be controlled.

Desiccant rotor, Process fan, Regeneration fan, Regeneration heater, Motor, Regeneration filter, Process filter, Controller,

Universal wheel, Process air duct, Regeneration air duct

manufacturing, and application research for more than ten years.

Design and manufacturing philosophy - In the process of designing and manufacturing desiccant dehumidifier, we are rigorous and serious to complete every detail with the philosophy of pursuing the essence and principle.

The optimization and serious selection of parts - optimize and improve the main components to ensure the product of high reliability and long service life. We cooperate with the best supplier in the world.

Dedicated to computer control technology combined with desiccant dehumidifier and other air conditioning systems to achieve all-weather and precise control by desiccant dehumidifier.

Packing & Delivery

To better ensure the safety of your goods, professional, environmentally friendly, convenient and efficient packaging services will be provided.

Packing & Delivery

To better ensure the safety of your goods, professional, environmentally friendly, convenient and efficient packaging services will be provided.

| Puresci is a global expert in the field of desiccant rotor and absorbing material. Over the past decades, we have been continuously setting new industry directions for the global market of desiccant rotor from the R&D of energy saving desiccant rotor, and technology of deep dehumidification, to the launch of Smart Solution Ecosystem of Desiccant Rotor Application. |

----- Why Choose Puresci -----

15+ Years' Experience

Large Supply Capacity

Win-win Cooperation

Technical Support

----- Services ------

1. Pre-sale Service

(1) Professional consultation.

(2) PC and mobile phone selection software.

(3) Support service - product test, system design, R&D technical support.

2. Medium-sales Service

Precise production facilities and consummate production technology, high quality guaranteed.

3. After-sales Service

Timely delivery, quickly help customers solve technical problem and optimize equipment performance,

ensure terminal customers to run dehumidification equipment smoothly and efficiently.

| Puresci is a global expert in the field of desiccant rotor and absorbing material. Over the past decades, we have been continuously setting new industry directions for the global market of desiccant rotor from the R&D of energy saving desiccant rotor, and technology of deep dehumidification, to the launch of Smart Solution Ecosystem of Desiccant Rotor Application. |

----- Why Choose Puresci -----

15+ Years' Experience

Large Supply Capacity

Win-win Cooperation

Technical Support

----- Services ------

1. Pre-sale Service

(1) Professional consultation.

(2) PC and mobile phone selection software.

(3) Support service - product test, system design, R&D technical support.

2. Medium-sales Service

Precise production facilities and consummate production technology, high quality guaranteed.

3. After-sales Service

Timely delivery, quickly help customers solve technical problem and optimize equipment performance,

ensure terminal customers to run dehumidification equipment smoothly and efficiently.

| What's your terms of trade? |

EXW, FOB, CFR, CIF, DDU, DDP. |

| What's your terms of payment? |

| T/T, L/C, Western Union or Paypal. |

| How about your delivery time? |

| It is 7 days normally. The specific delivery time depends on the items and the quantity of your order. |

| What's your terms of packing? |

The package of desiccant rotor is polyfoam and wooden case. It will be very safe for shipping. |

| Can you produce according to the samples? |

| Generally, we offer customized services. |

| What's your sample policy? |

| We can supply the sample if we have ready parts in stock, but the customers have to pay sample cost and courier cost. |

| What's your terms of trade? |

EXW, FOB, CFR, CIF, DDU, DDP. |

| What's your terms of payment? |

| T/T, L/C, Western Union or Paypal. |

| How about your delivery time? |

| It is 7 days normally. The specific delivery time depends on the items and the quantity of your order. |

| What's your terms of packing? |

The package of desiccant rotor is polyfoam and wooden case. It will be very safe for shipping. |

| Can you produce according to the samples? |

| Generally, we offer customized services. |

| What's your sample policy? |

| We can supply the sample if we have ready parts in stock, but the customers have to pay sample cost and courier cost. |

- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

Related Products

Related News

content is empty!

- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search