PST

Puresci

| Availability: | |

|---|---|

| Quantity: | |

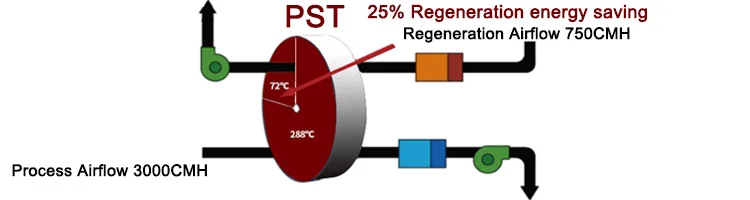

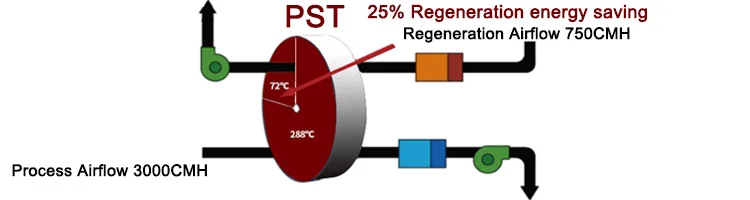

| Electricity Fee | Calculation Formula | Post Rotor Cooling Capacity | |

| Regular Desiccant Rotor | 293.46 | (120-35)*1.005*5000*1.2/3600/0.85*24*0.073=293.46 | 70KW |

| PST Desiccant Rotor | 220.095 | (120-35)*1.005*3750*1.2/3600/0.85*24*0.073=220.095 | 50KW |

| ROTOR SIZE | ||||

| Diameter(mm) | Thickness(mm) | Bearing/ Inner hole | Shaft Diameter(mm) | Delivered Knock-down |

| 180-550 | 50,100,150,200,300,400 | 6204/20 | 50 | NO |

| 600-850 | 200, 300, 400 | 6204/20 | 70 | NO |

| 965-1070 | 200, 300, 400 | 6204/20 | 100 | NO |

| 1200-1650 | 200, 300, 400 | 6206/30 | 150 | CAN |

| 1730-4250 | 200, 300, 400 | 6206/30 | 240 | YES |

| Electricity Fee | Calculation Formula | Post Rotor Cooling Capacity | |

| Regular Desiccant Rotor | 293.46 | (120-35)*1.005*5000*1.2/3600/0.85*24*0.073=293.46 | 70KW |

| PST Desiccant Rotor | 220.095 | (120-35)*1.005*3750*1.2/3600/0.85*24*0.073=220.095 | 50KW |

| ROTOR SIZE | ||||

| Diameter(mm) | Thickness(mm) | Bearing/ Inner hole | Shaft Diameter(mm) | Delivered Knock-down |

| 180-550 | 50,100,150,200,300,400 | 6204/20 | 50 | NO |

| 600-850 | 200, 300, 400 | 6204/20 | 70 | NO |

| 965-1070 | 200, 300, 400 | 6204/20 | 100 | NO |

| 1200-1650 | 200, 300, 400 | 6206/30 | 150 | CAN |

| 1730-4250 | 200, 300, 400 | 6206/30 | 240 | YES |

| Puresci is a global expert in the field of desiccant rotor and absorbing material. Over the past decades, we have been continuously setting new industry directions for the global market of desiccant rotor from the R&D of energy saving desiccant rotor, and technology of deep dehumidification, to the launch of Smart Solution Ecosystem of Desiccant Rotor Application. |

----- Why Choose Puresci -----

----- Services ------

(1) Professional consultation.

(2) PC and mobile phone selection software.

(3) Support service - product test, system design, R&D technical support.

Precise production facilities and consummate production technology, high quality guaranteed.

Timely delivery, quickly help customers solve technical problem and optimize equipment performance,

ensure terminal customers to run dehumidification equipment smoothly and efficiently.

----- Laboratory Display -----

| Mariana-Lab | |

Lake-Baikal-Lab |  | |

| Kilimanjaro Lab | |

----- Exhibition -----

Shenzhen International |

Refrigeration Exhibition 2021 | India Exhibition |

Lithium Battery Exhibition CIBF2021 | Rubber Show 2021 | Vietnam Exhibition |

| Puresci is a global expert in the field of desiccant rotor and absorbing material. Over the past decades, we have been continuously setting new industry directions for the global market of desiccant rotor from the R&D of energy saving desiccant rotor, and technology of deep dehumidification, to the launch of Smart Solution Ecosystem of Desiccant Rotor Application. |

----- Why Choose Puresci -----

----- Services ------

(1) Professional consultation.

(2) PC and mobile phone selection software.

(3) Support service - product test, system design, R&D technical support.

Precise production facilities and consummate production technology, high quality guaranteed.

Timely delivery, quickly help customers solve technical problem and optimize equipment performance,

ensure terminal customers to run dehumidification equipment smoothly and efficiently.

----- Laboratory Display -----

| Mariana-Lab | |

Lake-Baikal-Lab |  | |

| Kilimanjaro Lab | |

----- Exhibition -----

Shenzhen International |

Refrigeration Exhibition 2021 | India Exhibition |

Lithium Battery Exhibition CIBF2021 | Rubber Show 2021 | Vietnam Exhibition |

| What's your terms of trade? |

EXW, FOB, CFR, CIF, DDU, DDP. |

| What's your terms of payment? |

| T/T, L/C, Western Union or Paypal. |

| How about your delivery time? |

| It is 7 days normally. The specific delivery time depends on the items and the quantity of your order. |

| What's your terms of packing? |

The package of desiccant rotor is polyfoam and wooden case. It will be very safe for shipping. |

| Can you produce according to the samples? |

| Generally, we offer customized services. |

| What's your sample policy? |

| We can supply the sample if we have ready parts in stock, but the customers have to pay sample cost and courier cost. |

| What's your terms of trade? |

EXW, FOB, CFR, CIF, DDU, DDP. |

| What's your terms of payment? |

| T/T, L/C, Western Union or Paypal. |

| How about your delivery time? |

| It is 7 days normally. The specific delivery time depends on the items and the quantity of your order. |

| What's your terms of packing? |

The package of desiccant rotor is polyfoam and wooden case. It will be very safe for shipping. |

| Can you produce according to the samples? |

| Generally, we offer customized services. |

| What's your sample policy? |

| We can supply the sample if we have ready parts in stock, but the customers have to pay sample cost and courier cost. |